Solid carbide tools offer long tool life and faster cutting speeds than other substrates, but are more brittle and must be used with rigid tool-holding systems.

Tolerance of End Mill Diameter:

1 < D≤6 -0.010 ~ -0.030

6 < D≤10 -0.015 ~ -0.040

10 < D≤ 20 -0.020~-0.050

Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

Application

Used in Milling Machine.,CNC,Drill press,Engraving machine. Metal, woodworking, alloy steel, stainless steel, etc

2 flutes end mills is widely used in slotting, sinking etc.

3 flutes for aluminum.Bright finish for machining aluminum.

4 flutes, high rigidity, widely used in shallow slot, profile milling, and finish machining.

45° 2/4 Flutes Carbide End Mills

45° 2/4 Flutes Carbide End MillsColor: Dark grey.

Density: 14.5 g/cm3

Hardness: HRA 91.5

Grain Size: 0.8um

Bending Strength: 2800N/mm2

Raw material: Recycled material,YG10X with 10% Co content and 0.8um grain size. Because tungsten is a scarce resource, BK2045 series milling cutter is made of recycled tungsten steel.

Coating: ALTiN,High aluminum content provides excellent hot hardness and oxidation resistance.

A good choice for milling general steels weaker than HRC 30.

But, because of the aluminum content, it is not good choice for aluminum.  55° 2/4 Flutes Carbide End Mills

55° 2/4 Flutes Carbide End Mills

Color: Copper.

Density: 14.5 g/cm3

Hardness: HRA 92

Grain Size: 0.6um

Bending Strength: 3000N/mm2

Raw material: Use ZK30UF with 10%Co content and 0.6um grain size.

Coating: TiSiN, with very high surface hardness and good wear resistance.

Suitable for milling general steel under HRC 45, stainless steel, hardened steel, etc  65° 4 Flutes Carbide End Mills

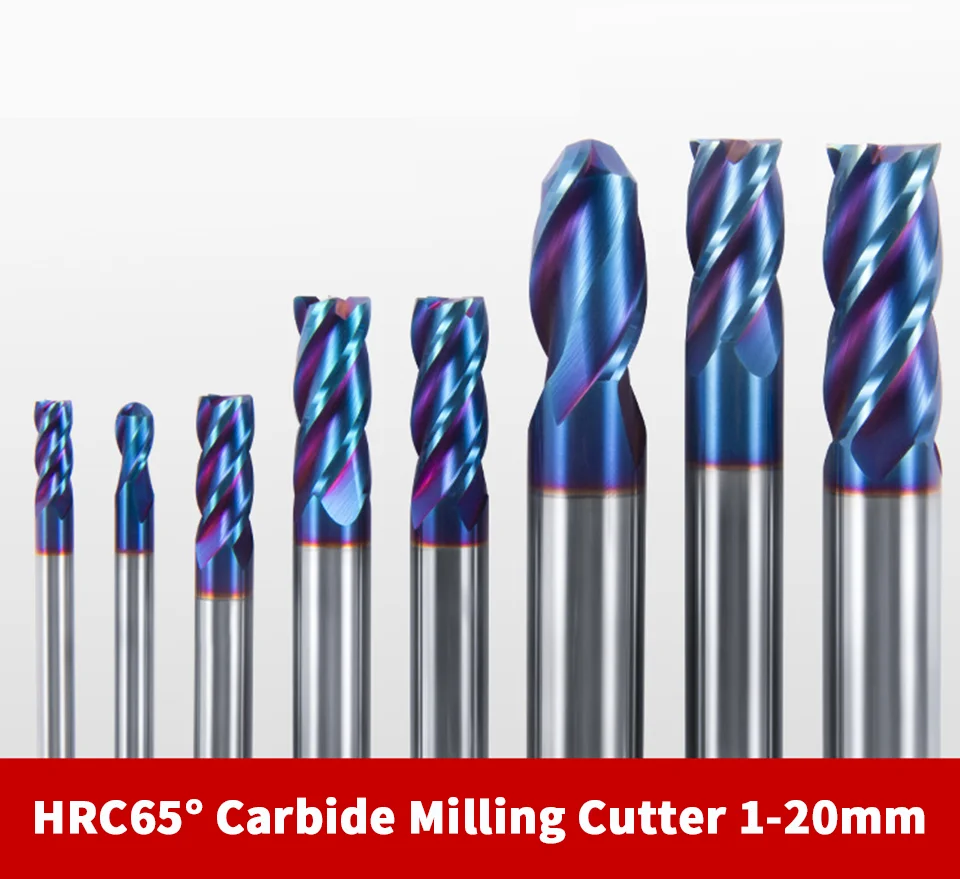

65° 4 Flutes Carbide End Mills

Color: Blue.

Density: 14.5 g/cm3

Hardness: HRA 93

Grain Size: 0.4um

Bending Strength: 4000N/mm2

Raw material: Use GU25UF with 12% Co content and 0.4um grain size.

Coating: AlTiSiN, with the hardness and thermal stability are up to 4000HV and 1200 ℃, respectively.

Suitable for machining stainless steel, hardened steel, titanium alloy, etc.HRc<55.

PS: The above data diameter is for reference, subject to actual cutting

Note: The above table is the standard value for side milling of the milling cutter. When the tool is used to process the keyway, the feed rate is 50%-60% of the table

When the rigidity of the machine tool and the installation is relatively poor, the product will vibrate and abnormal sound, at this time, the speed and feed should be reduced.

Note: It is recommended to be used on machining centers, engraving machines and other equipment.