⚝ FREE WORLDWIDE EXPRESS SHIPPING ⚝

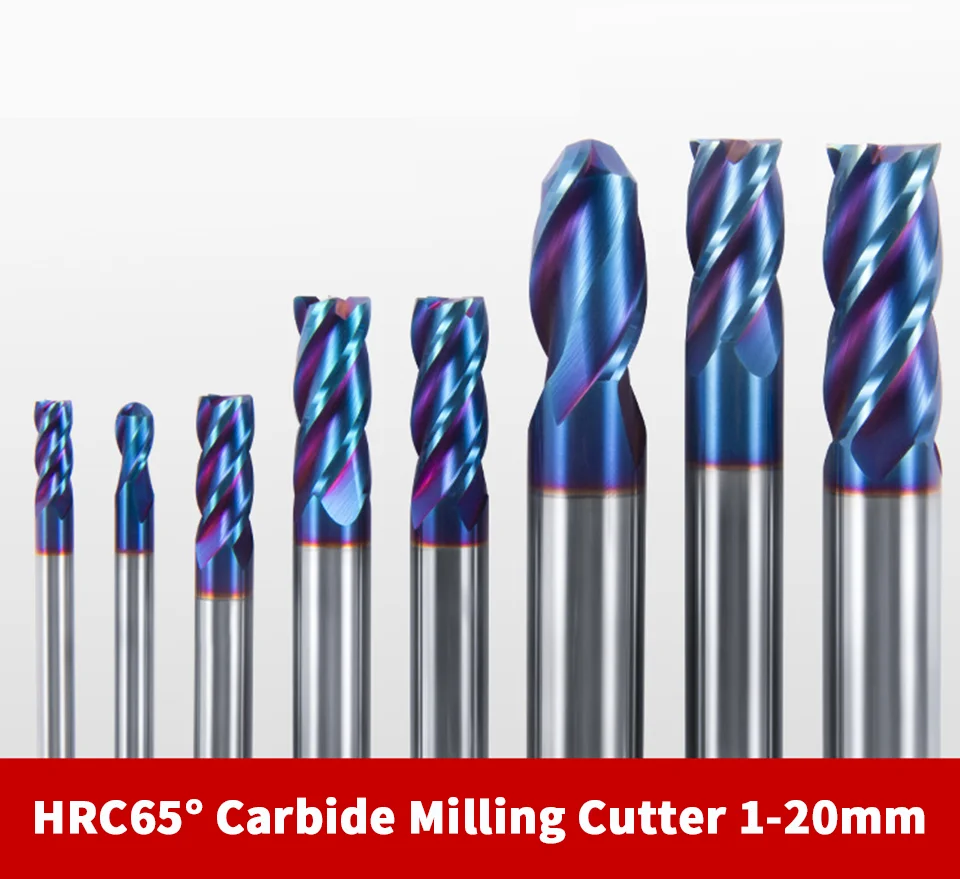

Carbide Radius End Cutter Mill Aluminium Cnc Milling Cutter For Metal Tungsten Steel CNC Maching Endmils

Cutting Edge Length: 2FHRC45

Dimensions: d1.5x4Dx4x50L

Product Details

Product Information:

Name: Tungsten steel end mill

Material: overall tungsten steel

Cutting hardness: HRC45°/55°/65°

Coating: Nano industrial titanium coating

Configuration equipment: machining center, CNC machine tool

Applicable processing materials: carbon steel, cast iron, die steel, alloy steel, tool steel, stainless steel, aluminum alloy, etc.

Our product advantages:

1. Using tungsten steel base material, it has higher wear resistance and red hardness

Strong performance, high temperature resistance, anti-burning

2. High-strength and large-capacity spiral chip flutes, integrally formed spiral, good versatility and durability

3. The large blade diameter design can greatly increase the stability and vibration resistance of the tool

4. Nano-coated blade, effectively reducing the number of tool changes, saving time, effort, and efficiency

5. Standard straight shank design, strong compatibility, tight occlusion, high bearing capacity, not easy to break

Solid carbide tools offer long tool life and faster cutting speeds than other substrates, but are more brittle and must be used with rigid tool-holding systems.

Tolerance of End Mill Diameter:

1 < D≤6 -0.010 ~ -0.030

6 < D≤10 -0.015 ~ -0.040

10 < D≤ 20 -0.020~-0.050

Coating:Good coating can improve tools life and production efficiency, as well as solve the cutting problems.

Application

Used in Milling Machine.,CNC,Drill press,Engraving machine. Metal, woodworking, alloy steel, stainless steel, etc

2 flutes end mills is widely used in slotting, sinking etc.

3 flutes for aluminum.Bright finish for machining aluminum.

4 flutes, high rigidity, widely used in shallow slot, profile milling, and finish machining.

45° 2/4 Flutes Carbide End Mills

45° 2/4 Flutes Carbide End Mills 55° 2/4 Flutes Carbide End Mills

55° 2/4 Flutes Carbide End Mills 65° 4 Flutes Carbide End Mills

65° 4 Flutes Carbide End Mills

PS: The above data diameter is for reference, subject to actual cutting

Note: The above table is the standard value for side milling of the milling cutter. When the tool is used to process the keyway, the feed rate is 50%-60% of the table

When the rigidity of the machine tool and the installation is relatively poor, the product will vibrate and abnormal sound, at this time, the speed and feed should be reduced.

Note: It is recommended to be used on machining centers, engraving machines and other equipment.

Worldwide Free Shipping

Over 4 Million Happy Customers

Award-Winning Customer Support

Share on:

You may also like

Recently view

Related Searches

Today Only: Seret privileges for you!

Have a look at our Privacy Policy to understand how we process your data for marketing emails