⚝ FREE WORLDWIDE EXPRESS SHIPPING ⚝

| English (EN) | USD

Carbide T Slot Milling Cutter CNC Tools For Metal Aluminium Steel Machining Tungsten Steel T-Groove End Mills 3 4 5 6 7 8 9 10mm

$13.99 USD$14.29 USD

Cutting Edge Length: Uncoated

Dimensions: D3x50L

Cutting Edge Diameter: H1.5

Report This Product

Product Details

Carbide T Slot Milling Cutter Tungsten CNC Tool Metal Al Steel Copper Machining 3mm 4mm 6mm 8mm 10mm 12mm

Product Information

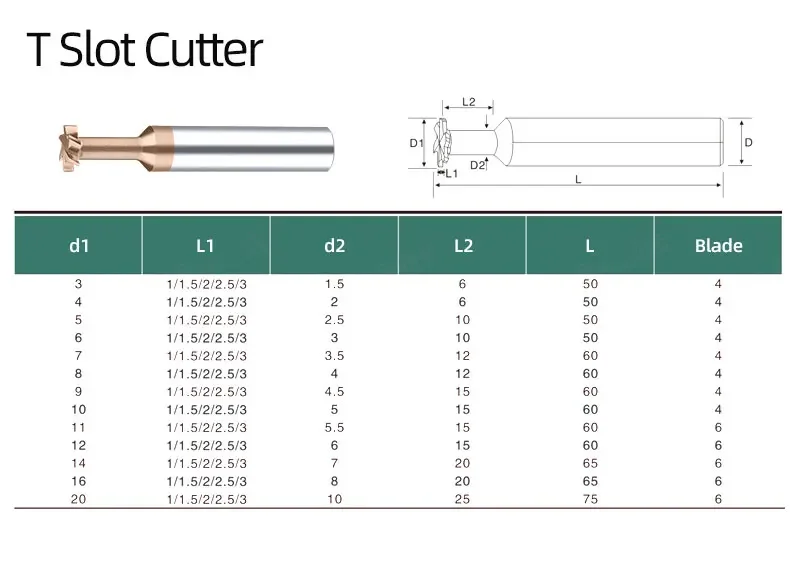

Name: T-slot Milling Cutter

Material: Tungsten steel/Cemented carbide

Cutting hardness: HRC45/55°

Cutting height: 1 1.5 2 2.5 3 4 5mm

Coating: Uncoated/Nanocoated

Configuration equipment: CNC milling machine, vertical milling machine and machining center and other equipment

Applicable materials: iron plate, stainless steel, cast iron, titanium alloy, hardened steel and other metal materials

Features:

1. Strong wear resistance: tungsten steel material has high hardness and wear resistance, so that T-slot milling cutter can maintain good cutting performance for a long time.

2. Good cutting effect: tungsten steel T-slot milling tool has excellent tool geometry and cutting edge design, which can produce smooth and accurate T-slot cutting surface.

3. Efficient machining: The structural design of T-slot milling cutter makes the cutting force dispersed, the cutting efficiency is high, and the processing efficiency and production benefit can be improved.

Notice:

1. When using tungsten steel T-slot milling cutter, the appropriate tool speed, feed speed and cutting depth should be selected according to the specific workpiece material and cutting data to ensure the cutting effect and tool life.

2. During the machining process, the wear of the milling cutter should be checked regularly. Once the milling cutter is obviously worn or damaged, it should be replaced in time to ensure the quality and safety of cutting.

3. Please carefully read and abide by the instruction manual of the milling cutter before use, and install and use the milling cutter correctly to avoid accidents and damage to the equipment.

4. If the product you received is damaged, incorrect or any other problem, please contact us for assistance.

5. If you are satisfied with our products and services, please leave 5 star feedback, we will appreciate it.

Worldwide Free Shipping

Over 4 Million Happy Customers

Award-Winning Customer Support

Share on:

You may also like

Recently view

Related Searches

WORLDWIDE FREE SHIPPING - AWARD-WINNING CUSTOMER SERVICE- 2 MILLION+ HAPPY CUSTOMERS

WORLDWIDE FREE SHIPPING - AWARD-WINNING CUSTOMER SERVICE- 2 MILLION+ HAPPY CUSTOMERS

WORLDWIDE FREE SHIPPING - AWARD-WINNING CUSTOMER SERVICE- 2 MILLION+ HAPPY CUSTOMERS

WORLDWIDE FREE SHIPPING - AWARD-WINNING CUSTOMER SERVICE - 2 MILLION+ HAPPY CUSTOMERS

Today Only: Seret privileges for you!

Have a look at our Privacy Policy to understand how we process your data for marketing emails