⚝ FREE WORLDWIDE EXPRESS SHIPPING ⚝

Self-Priming Stainless Steel Oil Pump – 220V/380V Gear Pump for High Viscosity Engine Oil, Diesel, Edible Oil, Hydraulic Oil

$187.99 USD$403.19 USD

This deal will end in

Voltage: 220V

Product Details

Self-Priming Stainless Steel Oil Pump - JG-30

Overview

The JG-30 self-priming stainless steel oil pump represents a robust and versatile solution for transferring various types of viscous fluids, encompassing engine oil, diesel fuel, edible oils, and hydraulic fluids. Its construction from high-grade stainless steel ensures durability and suitability for both industrial and food-grade applications. This document details the key features, specifications, and operational procedures of the JG-30 oil pump.

Product Specifications and Features

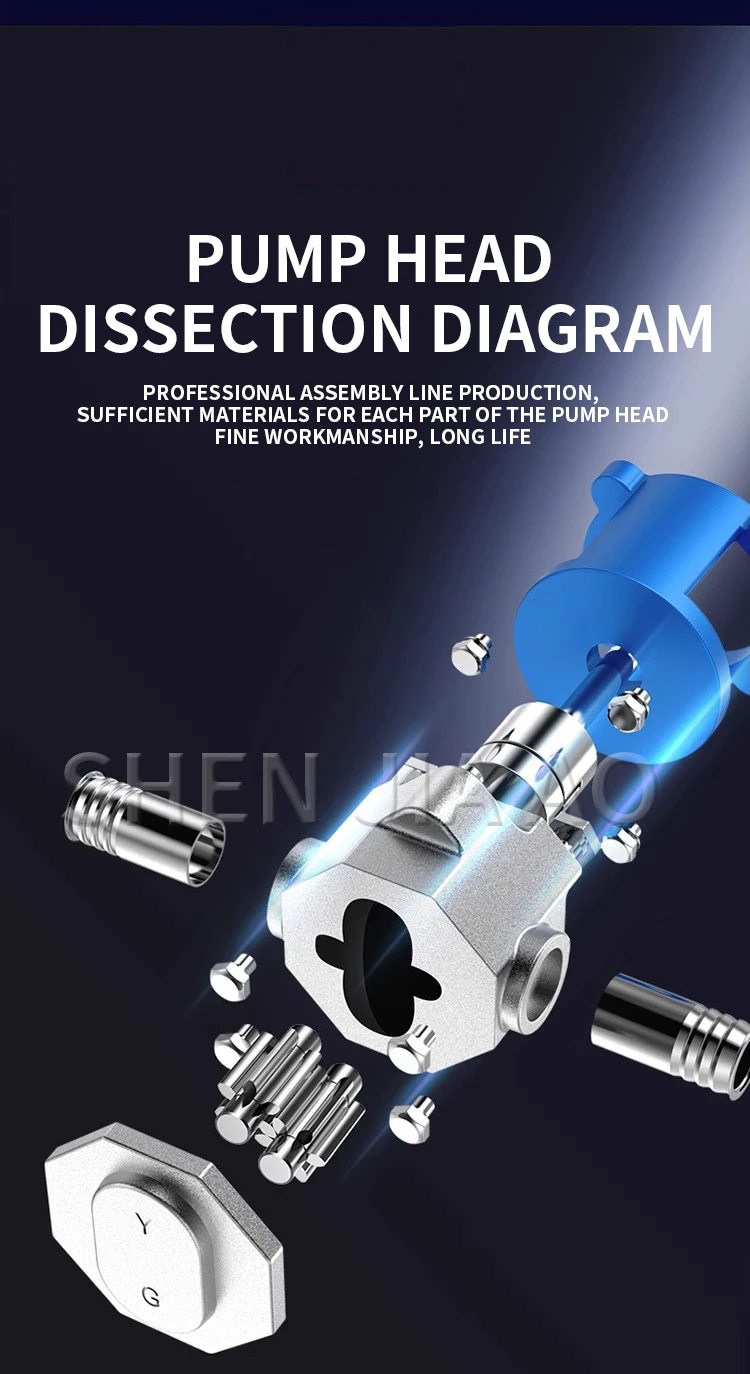

This industrial-grade, food-grade oil pump boasts a compact design while maintaining significant performance capabilities. The meticulous construction utilizing stainless steel minimizes the risk of corrosion and ensures prolonged operational life, particularly when handling potentially corrosive substances. The gear mechanism, renowned for its efficiency in handling high-viscosity fluids, constitutes a critical component of the pump’s operational performance. The pump's ability to self-prime eliminates the need for auxiliary priming mechanisms, streamlining the setup and operation process.

The JG-30's specifications are meticulously designed to accommodate a wide range of application requirements. The pump supports both 220V and 380V voltage inputs for global applicability. The specified flow rate of 30 liters per minute, coupled with a maximum lift of 30 meters and a suction height allowance of 4 meters, signifies robust performance. Importantly, the 25mm caliber ensures smooth and efficient fluid transfer. The 370W power output further attests to the unit’s ability to handle demanding applications. The compact physical dimensions of 170mm x 380mm x 260mm contribute to its ease of integration into various working environments.

Operational Considerations

Ensuring optimal performance and longevity requires meticulous attention to operational parameters. Prior to initiating operations, meticulous verification of the electrical connection is crucial. Confirming compatibility with the local voltage source minimizes potential hazards and ensures optimal functionality.

The pump's self-priming mechanism facilitates initial operation without the need for pre-filling. However, it is imperative to ensure that the suction line is fully submerged in the fluid reservoir to allow for proper priming. A partial immersion might impede the priming process. For applications involving changes in fluid levels or elevation differences, consider the limitations of the suction height and the pump's lift capacity.

Maintenance and Troubleshooting

Regular maintenance plays a pivotal role in maintaining peak performance and longevity. This entails routine inspection of all moving parts and seals to identify and mitigate potential wear or degradation. Visual inspection for leaks, ensuring proper lubrication, and inspecting the pump's electrical connections are crucial components of preventative maintenance.

Should the pump exhibit any unusual operating behavior, such as reduced flow rate, audible noises, or unusual vibrations, immediate troubleshooting is required. The troubleshooting process should begin with verifying appropriate voltage, ensuring the suction line is submerged, and assessing the cleanliness and proper lubrication of moving parts. If the issue persists, consultation with qualified maintenance personnel is highly advisable.

Safety Precautions

The operation of any power-driven equipment demands adherence to safety protocols. Electrical connections must be checked thoroughly and securely installed to prevent the risk of electric shock. Ensuring proper grounding procedures and adhering to relevant safety standards are paramount. When handling fluids, appropriate personal protective equipment (PPE) must be employed to mitigate any potential health hazards.

Application Examples

The JG-30 self-priming oil pump is adept for a diverse range of industrial and commercial applications. Its corrosion-resistant construction makes it ideal for various industries, including manufacturing, automotive repair, and food processing facilities. Consider applications such as:

- Fueling stations: Efficient transfer of fuel to storage tanks or vehicles.

- Industrial plants: Transporting various viscous fluids within the plant environment.

- Hydraulic systems: Supplying hydraulic fluids to operate machinery.

- Food processing: Handling edible oils for processing and distribution tasks.

Warranty and Support

This product is covered by a [insert warranty details here] warranty. In cases of required service or support, comprehensive documentation and contact information are available at [insert contact information here] . Our dedicated technical support team is readily available to address any queries or concerns.

Disclaimer

This document provides general guidance on the proper usage of the JG-30 oil pump. Users should always consult pertinent safety regulations and local guidelines for their particular application. We are not liable for any damages or losses resulting from improper use.

Name: Self-priming oil pump

Specifications: Industrial Grade/Food Grade

Model: JG-30

Suction: 4M

Lift: 30M

Caliber: 25

Flow: 30L/min

Voltage: 220V/380V

Power: 370W

Size: 170*380*260MM

Worldwide Free Shipping

Over 4 Million Happy Customers

Award-Winning Customer Support

Share on:

You may also like

Recently view

Related Searches

Today Only: Seret privileges for you!

Have a look at our Privacy Policy to understand how we process your data for marketing emails