⚝ FREE WORLDWIDE EXPRESS SHIPPING ⚝

The HI-LO welding gage bridge cam weld gage

$25.99 USD$36.39 USD

Product Details

The HI-LO Welding Gage: A Comprehensive Inspection Tool for Weldments

Introduction

Precise measurement and inspection are crucial in ensuring the quality and structural integrity of welded components. The HI-LO welding gage, a versatile and sophisticated instrument, caters to this imperative. This instrument, specifically, the HI-LO gage, bridge cam weld gage, and HI LO Gage Test Ulnar Welder Inspection, provides a comprehensive suite of functionalities for assessing various weld parameters, contributing to a more efficient and reliable inspection process. This document details the instrument's features, operational procedures, and potential applications.

Product Overview

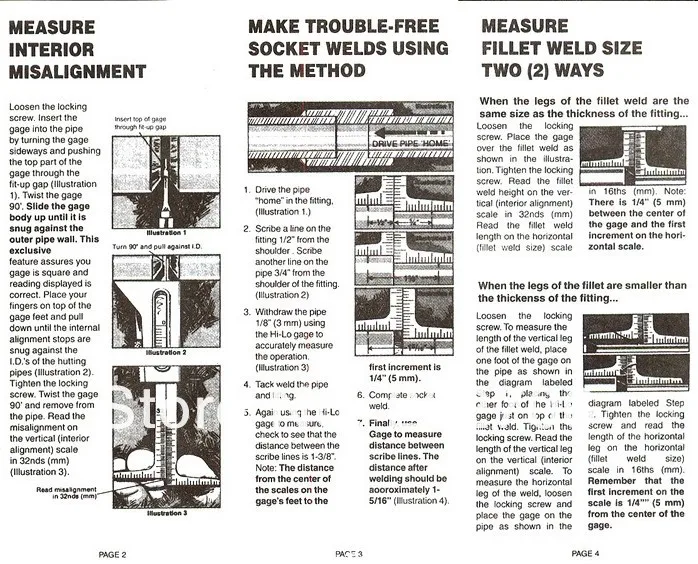

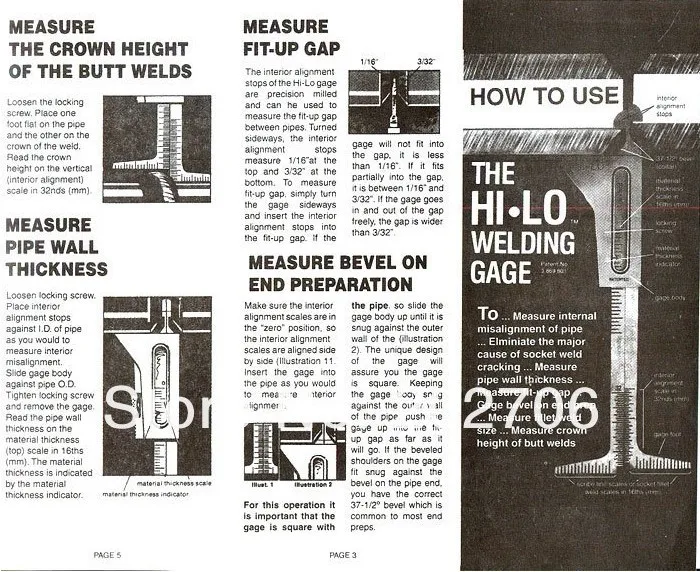

The HI-LO welding gage is a specialized tool designed for accurate measurement and analysis of welds. It transcends a simple measuring device, offering sophisticated capabilities. The instrument, also known as the bridge cam weld gage and referenced as the HI LO Gage Test Ulnar Welder Inspection, facilitates the determination of diverse weld characteristics. This includes the height of both flat and fillet weld beads, as well as internal and external misalignment within the weldments. Crucially, it allows for the measurement of the weldments' wall thickness. These comprehensive functionalities underscore the instrument's value in a quality control environment.

Technical Specifications (Illustrative)

While precise specifications are not provided in the product description, the following are suggestive of typical performance parameters for such an instrument. These values should be verified from the manufacturer for a particular model.

- Measuring Range (Height): [Insert appropriate range measured in suitable units, e.g., millimeters, inches]

- Accuracy: [Insert appropriate accuracy in same units as measuring range, e.g., +/-X mm]

- Resolution (Height): [Insert suitable resolution figure, e.g., 0.01 mm]

- Measuring Range (Misalignment): [Specify range for both internal and external misalignment. Include units. ]

- Accuracy (Misalignment): [Units and specific error figures for both internal and external misalignment. ]

- Material Compatibility: [List materials for which the gage is designed and suitable for]

- Operating Temperature: [Temperature range in which the gage is designed to operate]

Key Features and Capabilities:

The HI-LO welding gage's distinctive features highlight its value proposition. The tool's capabilities span from basic height measurement to assessing intricacies such as wall thickness and misalignment, making it a crucial component within weld inspection and quality control procedures.

- Versatility: The instrument's capacity to assess the height of flat and fillet weld beads distinguishes it from simpler measuring tools.

- Comprehensive Measurement: The gage's ability to precisely measure both internal and external weld misalignment allows for an in-depth evaluation of the weld's geometry, offering crucial insights into the quality and uniformity of the weld.

- Accuracy and Precision: Highlighted by the instrument's ability to determine precise weld parameters. This characteristic ensures the evaluation of weldments’ structural integrity and suitability for application.

- Efficiency: The instrument's ability to combine multi-parametric measurement in a single unit allows for a streamlined inspection process.

Operational Procedures

Proper operation of the HI-LO welding gage is paramount for achieving accurate results. The following steps outline the general procedure.

- Preparation: Ensure the weldment is clean and free from excess material or debris that could impede the accuracy of the measurement process.

- Alignment: Position the gage on the weldment ensuring proper alignment for the different measured parameters. Specific procedures for ensuring accurate alignment should be provided by the manufacturer.

- Measurement: Engage the relevant measuring mechanisms to obtain the required data by activating all the associated levers or components according to the manufacturer's specifications.

- Reading and Recording: Record the data obtained from the inspection. The instrument should ideally provide a clear and concise read-out or display, facilitating the registration of measurements. A calibrated approach to recording the gathered data is critical for maintaining consistency and precision in the overall inspection protocol. Proper data recording can be crucial in following industry-standard inspection requirements.

- Verification: A verification step (where applicable) to remeasure or cross-verify certain parameters is desirable to confirm the accuracy of the initial assessment.

Applications and Use Cases

The adaptability of the HI-LO welding gage makes it a suitable tool in a variety of contexts, including but not limited to:

- Structural Fabrication: The gage's capabilities in structural inspections are suitable for assessing the integrity of welded structures, such as bridges, buildings, and tanks.

- Automotive Manufacturing: Measurement of weld bead height, weld penetration, position, and misalignment are crucial during automotive assembly processes, and this gage can serve to ensure high-quality standards.

- Pipeline Construction: Pipelines necessitate high standards of precision, demanding that welds be thoroughly examined for any deviation from specifications.

- Shipbuilding/Marine Industry: Weld quality inspection is a critical step in shipbuilding for safety and structural integrity.

- Aerospace Industry: Critical components in the aerospace industry require highly accurate weld evaluation to maintain structural integrity and safety.

Maintenance and Calibration

Regular maintenance and calibration are imperative to sustain the accuracy and reliability of the HI-LO welding gage. Specific recommendations for the maintenance routine, including cleaning and lubrication procedures, will be detailed in the instrument's user manual. Calibration by a certified technician should be performed periodically to confirm that the instrument remains within its acceptable tolerance levels.

Conclusion

The HI-LO welding gage provides an essential tool for the welding industry, and allied commercial enterprises operating in any field requiring precise and comprehensive weld assessment. Its capacity to measure critical weld parameters like height, misalignment, and wall thickness, combined with its robust design, ensures quality control, accuracy, and safety in a variety of industrial settings. Consult the manufacturer's detailed documentation, including the user manual, for precise operating procedures, specific calibration protocols, and comprehensive specifications.

Worldwide Free Shipping

Over 4 Million Happy Customers

Award-Winning Customer Support

Share on:

You may also like

Recently view

Related Searches

Today Only: Seret privileges for you!

Have a look at our Privacy Policy to understand how we process your data for marketing emails