⚝ FREE WORLDWIDE EXPRESS SHIPPING ⚝

V6 / Volcano / MK8 Hotend / Neptune4 / K1 Nozzle

$14.99 USD$24.89 USD

Color: Neptune

Size: 0.6mm

Product Details

The V6 / Volcano / MK8 Hotend / Neptune4 / K1 Nozzle: A Bastion of Precision and Durability for 3D Printing

This document details the specifications, functionalities, and operational considerations of the V6 / Volcano / MK8 Hotend / Neptune4 / K1 Nozzle DLC Hardened Steel & Copper Wear Resistant Bimetal HC Nozzle, a cutting-edge 3D printing component designed for exceptional performance and longevity.

An Overview of Exceptional Performance

The V6 / Volcano / MK8 Hotend / Neptune4 / K1 Nozzle represents a significant advancement in 3D printing technology. Its meticulous design, leveraging a unique bimetallic approach, is specifically tailored for the intricate demands of high-strength carbon fiber material extrusion. This results in remarkably enhanced durability and superior flow rates. This enhanced performance directly translates to higher quality printed parts, superior print consistency, and reduced downtime.

The Pinnacle of Material Integration: Innovative Bimetallic Design

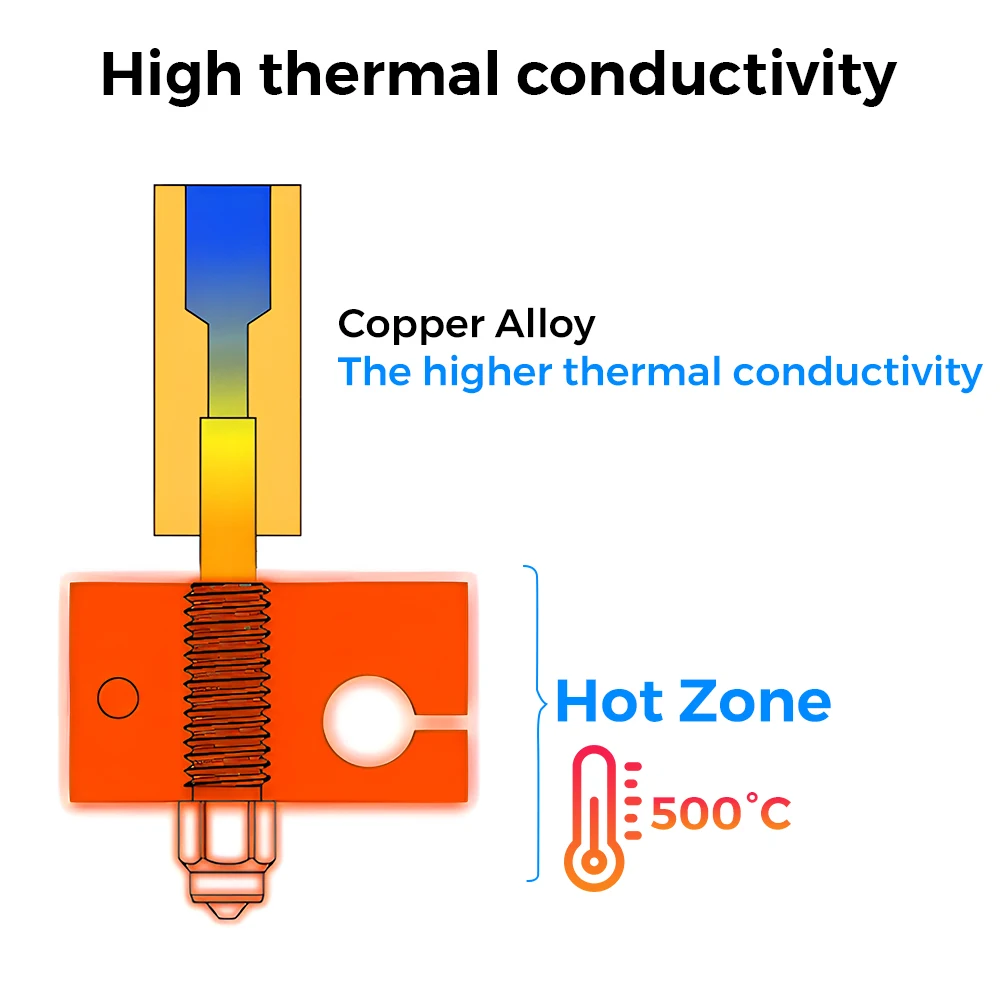

This nozzle's extraordinary capabilities stem from its innovative bimetallic core. The design strategically incorporates hardened steel near the nozzle tip, seamlessly integrated with a high-thermal conductivity copper body. This ingenious architecture addresses the inherent trade-offs often associated with traditional all-metal nozzles.

By transitioning to hardened steel near the nozzle tip, the nozzle achieves superior wear resistance, enabling prolonged use when interacting with abrasive materials like carbon fiber. Simultaneously, the high thermal conductivity of the copper body facilitates rapid heat distribution, ensuring consistent temperatures throughout the printing process. This thermal efficiency is paramount in achieving smooth, consistent print outcomes. The resultant effect is a significant reduction in print inconsistencies, improved precision, and a substantial increase in the lifespan of the nozzle. Compared to comparable all-copper or all-hardened steel nozzles, this design demonstrably surpasses limitations in both durability and flow rates.

Fortifying the Tip: Hardened Steel and DLC Treatment

The nozzle's superior wear resistance is further enhanced by the application of hardened steel at the critical nozzle tip. The crucial tip area is additionally treated with Diamond-Like Carbon (DLC). This advanced DLC treatment provides an exceptionally hard, wear-resistant surface, crucial when printing with abrasive materials such as carbon fiber. This layer not only extends the nozzle's lifespan by mitigating premature wear but also preserves the accurate geometry of the nozzle tip, maintaining optimal flow rates over extended periods of usage.

Maintaining Consistency Through Thermal Efficiency: High-Thermal Conductivity Copper Body

The copper body of the nozzle, renowned for its exceptional thermal conductivity, plays a critical role in ensuring consistent performance and reducing print inconsistencies. Copper rapidly transmits heat throughout the nozzle, rapidly achieving and maintaining the optimal temperature required for the extrusion process. This ensures a steady and consistent flow of material, directly contributing to the high quality and reliability of the printed output. The precise temperature regulation contributes to the overall quality and consistency of the print.

Preservation of Performance: Nickel Plating

The surface of the nozzle is treated with nickel plating. This crucial process prevents copper oxidation, a significant concern in high-temperature applications. Maintaining the pristine state of the copper surface ensures sustained high performance and extended durability. This crucial step in the manufacturing process prevents deterioration of the copper body, ensuring the reliability of the nozzle for prolonged operation. The resulting longevity minimizes downtime and facilitates higher production rates.

Precision Engineering: High-Precision CNC Machining

The nozzle's high-precision CNC machining contributes significantly to its exceptional performance. The internal surface is meticulously machined, achieving a remarkable level of smoothness – 0.4 microns. This translates to remarkably more accurate printing and substantially reduced residue buildup within the nozzle. This exceptional level of precision ensures consistent flow of material, reduced nozzle clogging, and an overall improvement in the quality of the printed parts. The reduction in residue contributes to clean prints with minimal artifacts and defects.

Operational Considerations: Ensuring Optimal Performance

When utilizing the V6/Volcano/MK8 Hotend/Neptune4/K1 Nozzle, meticulous attention to operating parameters is essential to maximize its performance and longevity. Proper calibration of the 3D printer's temperature control system is paramount for achieving optimal results. Calibration should align with the specific material being used. Care must be taken to avoid overheating the nozzle, as this can compromise the tip's integrity and compromise print quality. Frequent checks of the nozzle temperature and material flow rate are encouraged to avoid any malfunctions or irregularities during printing. Cleaning the nozzle at regular intervals is essential, especially when printing high abrasion materials, to minimize clogging and maintain consistent performance.

Conclusion: Elevating 3D Printing Capabilities

The V6/Volcano/MK8 Hotend/Neptune4/K1 Nozzle is a culmination of advanced engineering principles, providing a solution for the high demands of 3D printing applications, particularly those involving high-performance materials like carbon fiber. Its combination of durability, precision, and thermal efficiency will deliver exceptional results for professionals and enthusiasts alike, significantly enhancing the print quality and efficiency of a diverse range of 3D printing designs and project

Worldwide Free Shipping

Over 4 Million Happy Customers

Award-Winning Customer Support

Share on:

You may also like

Recently view

Related Searches

Today Only: Seret privileges for you!

Have a look at our Privacy Policy to understand how we process your data for marketing emails